|

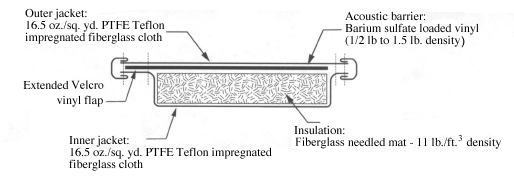

Blanket Construction

Blanket construction is a double sewn lock stitch with a 7 stitches per inch minimum. All raw jacket edges have a tri-fold Teflon cloth binding stitched with Teflon coated fiberglass thread. No raw cut jacket edge will be exposed.

Resistant Flap

To avoid penetrating noise at mating seams, blanket pieces will include an extended 2" wide fabric vinyl flap. This flap will cover the exposed seam and will minimize any potential noise leaks.

ID Plates

For easy identification and location, a stainless steel or aluminum name plate tag is riveted to each blanket piece. 1/8" Embossed lettering shows location, description, size, pressure rating and tag number sequence.

Quality Pins

To enhance blanket quality and to maintain uniform thickness, stainless steel quilting pins will be placed at random locations no greater than 18" apart. This will prevent shifting of the insulation filler.

Blanket Insulation Weight

When designing blanket insulation for large equipment where a multi-piece construction is necessary, the total number of pieces will be minimized. Any one piece will not exceed 50 lbs. in weight.

Assembly Drawing Requirements

Each blanket insulation project will include an instruction package shipped with the blanket material. This package will include Assembly Drawings identifying piece location, a Material List of all pieces and Instructions for Installation on how blanket insulation will be installed. The latest and most accurate records must be kept by the supplier on a CAD file for a minimum of ten years to assure re-orders and replacement.

Guaranteed Fit

All blanket designs will accommodate vibration probes, gauges, tubing, piping, brackets, etc. All blanket pieces are guaranteed to fit for optimum acoustic performance.

Standard Fastener

A 20 gauge stainless steel wire is doubled up and twisted in a spiral fashion with a minimum of 4 twists per inch. Wiretwist length will be 16" or longer. The Wiretwist will be secured to the lacing pin at the pin stem. Lacing pin stems will be 14 gauge.

Fastening Options:

1. Velcro Flaps

A 2" wide hood will be stitched to the blanket and a 2" wide loop will be stitched to an extended outer jacketing flap. Velcro is rated for temperatures to 350º F.

2. Stainless Steel "D" Ring Strap with Velcro Tab

A three layer fabric strap is double sewn. One strap is a 16" long pulldown strap, the other is a 6" long stationary strap. Both straps are stitched to the outer jacketing of the blanket. The stationary strap includes a 304 stainless steel "D" ring measuring 1.125" to 1.25" in width. This is placed 1/2" from the closing seam edge. The pulldown strap is placed 3" in from the closing seam edge. Both matching straps are spaced along the closing seam edge no greater than 8" apart. The pulldown strap includes hook-and-loop velcro, measuring at least 1" wide by 6" long, and is perimeter stitched to the strap surface. All closing seams have a 1.5" extended fabric flap, which is placed along the stationary strap side of the closing seam.

Design Guidlines

To access the true limitations of this recommended design, refer to the technical data sheets on each product component. Following these guidelines will produce the highest achievable service life. Blanket design quality can be reduced or enhanced by changing any one component. If a question arises regarding deviations from those stated guidelines, please contact your regional representative or call Shannon direct.

Project Qualifications

All items to be insulated will require a field takeoff prior to bid submittal, and must be reviewed for proper cost estimation. Upon receipt of project contract, each and every item must be accurately measured for retrofitting to existing field conditions and tagged with an aluminum or stainless steel identification tag showing an item number for installation reference. At the time of installation, blankets must have a corresponding item number shown on the blanket tag and must match to existing tagging on fitting. No standard blanket designs will be accepted. This will assure good thermal performance.

Warranties

All blankets will carry an 18 month warranty covering the replacement cost of the blanket. This warranty will cover blanket failure due to premature degradation from either blanket components used in the blanket, the blanket design construction or workmanship.

|