|

||||

|

INSULTECH |

||||

|

|

||||||||

|

Service |

Temperature |

Permeability |

Outdoor Use |

Chemcial Resist |

Abrasion Resist |

Fire Rating |

||

|

Fº |

Cº |

Pervious |

Impervious |

|

||||

|

Steam |

800 |

427 |

x |

|

Good |

Excellent |

Good |

Self-Extinguishing |

|

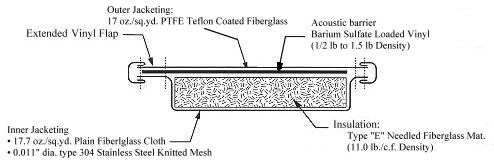

Application Exhaust Duct • PRV Stations • Steam Turbines • Fan Housings • Centrifugal Compressors • Silencers • Machinery • Turbochargers • Process Piping & Fittings Market Equipment operating above OSHA required sound limits • Commercial Industrial OEM Design Components: |

||||

|

||||

|

Blanket Thickness Surface Temperature Reference: |

||||||

|

Operating Temperature |

Thickness/Surface Temperature |

Thickness/Surface Temperature |

Thickness/Surface Temperature |

|||

|

450ºF (232ºC) |

1" |

135ºF |

1.5" |

118ºF |

2" |

108ºF |

|

550ºF (288ºC) |

1" |

154ºF |

1.5" |

132ºF |

2" |

120ºF |

|

650ºF (343ºC) |

1" |

175ºF |

1.5" |

148ºF |

2" |

133ºF |

|

750ºF (399ºC) |

1" |

197ºF |

1.5" |

165ºF |

2" |

147ºF |

|

800º F (454ºC) |

1" |

208ºF |

1.5" |

174ºF |

2" |

154ºF |

|

|

||||||

|

Blanket Thickness to Acoustic Performance: |

||

|

DBA Reduction Range |

Thickness |

Surface Mass |

|

2-5 DBA |

1" |

1.38 - 2.38 lb/SF |

|

6-10 DBA |

1.5" |

1.82 - 3.10 lb/SF |

|

11-15 DBA |

2" |

2.5 - 3.51 lb/SF |

|

|

||

|

Fabrication Requirements Blanket Construction Barium Sound Protection Minimized Void Leaks ID Plates Quality Pins Blanket Insulation Weight Assembly Drawing Requirements Design Requirements Guaranteed Fit Standard Fastener Design Guidelines Project Qualifications Warranties |

|||

|

|

|||||